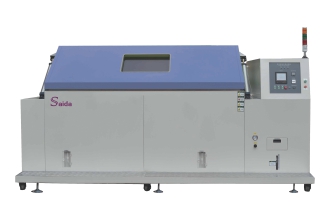

鹽霧試驗機SD-CF系列

型號:SD-1200CF/SD-1600CF/SD-2000CF

本試驗設備主要用于確定裝備上的材料和表面涂層耐受酸性大氣影響的能力,試驗適用于可能在酸性大氣地區(qū)(如工業(yè)區(qū)或燃燒設備的廢氣附近)儲存或使用的裝備。也可以用于模擬人造環(huán)境中...

服務熱線:0794-7512888

產(chǎn)品詳情

本試驗設備主要用于確定裝備上的材料和表面涂層耐受酸性大氣影響的能力,試驗適用于可能在酸性大氣地區(qū)(如工業(yè)區(qū)或燃燒設備的廢氣附近)儲存或使用的裝備。也可以用于模擬人造環(huán)境中的腐蝕試驗,用于檢驗金屬材料有或無防腐蝕保護比較質(zhì)量的方法;適合于快速分析有機和無機涂層中的不連續(xù)性、孔和損壞等現(xiàn)象的防腐蝕試驗,此外,為質(zhì)量控制的目的,能在涂有相同涂料的試樣之間進行比較;鹽霧試驗特別適用于檢測某些金屬、有機、陽極氧化和轉(zhuǎn)化涂層中的不連續(xù)性,如小孔和其他缺陷;設備不適用于評價硫化氫的影響。This equipment is mainly used to determine the material and surface coatings on the equipment's ability to withstand the effects of acid atmosphere. The test is suitable for equipment that may be stored or used in acidic atmosphere areas, such as industrial areas or near the exhaust gas of combustion equipment. It can also be used to simulate corrosion tests in man-made environments and to test the quality of metal materials with or without corrosion protection. It is suitable for rapid analysis of discontinuity, pore and damage in organic and inorganic coatings. In addition, for the purpose of quality control, it can be used to test the same coatings. Salt spray test is especially suitable for detecting discontinuities in some metals, organic, anodic oxidation and conversion coatings, such as holes and other defects; equipment is not suitable for evaluating the effect of hydrogen sulfide.